Prevention Is Better Than Cure: The Importance of Driveshaft Maintenance

For any vehicle—whether a family car, commercial truck, or an entire fleet—the driveshaft (CV Joint) is a critical component that ensures smooth operation. Yet, this quietly working part is often overlooked until a failure occurs. A faulty driveshaft can lead to expensive repairs, vehicle breakdowns on the road, safety risks, and operational losses. This article provides practical tips for routine driveshaft maintenance and inspection to help reduce failure rates and save long-term maintenance costs.

First Line of Defense: Regular Visual Inspection of the CV Boot

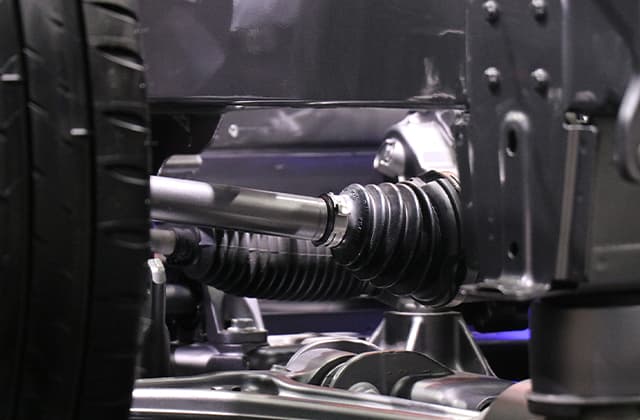

The CV boot is the primary and most important protective barrier for the driveshaft's internal precision joint. Made of rubber or thermoplastic, the boot prevents water, dust, and debris from entering and ensures that the internal lubricating grease does not leak.

- Inspection Focus: Check the surface of the boot regularly (for example, during every oil change) for cracks, tears, or other signs of damage.

- Warning Signs: Look for grease splatter on the inside of the tire or around the driveshaft. This usually indicates a torn boot and leaking grease. Early detection and replacement of a small boot costs far less than replacing the entire driveshaft.

Listen for Warnings: Identifying Driveshaft Fault Noises

As driveshafts wear, they often produce specific noises that can alert you to early issues. Learning to recognize these sounds is key to timely maintenance.

- "Clicking" when turning: This is the most typical early warning of driveshaft failure. If you hear a rhythmic "click" or "clack" coming from the wheels while turning or accelerating, it usually indicates severe wear of the outer CV joint.

- "Humming" or vibration during straight driving: If the vehicle vibrates abnormally or produces a continuous humming noise during straight-line acceleration or deceleration, this may indicate an issue with the inner CV joint or overall driveshaft balance.

Professional Repairs and Quality Parts: Reducing Maintenance Costs at the Source

If any of the warning signs above appear, seek professional inspection immediately. Timely intervention can prevent further damage. When replacement is needed, choosing the right parts is critical for long-term cost management.

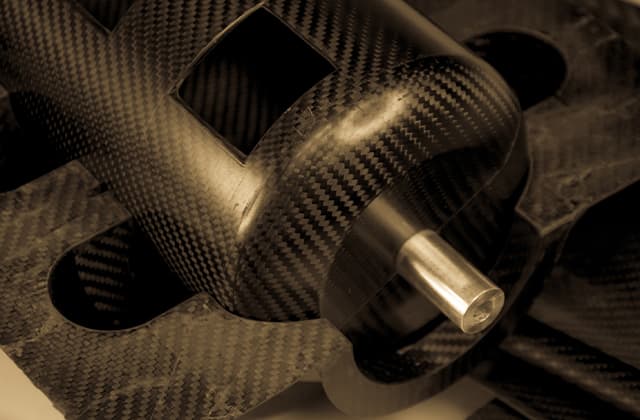

- Don’t go cheap: Low-cost driveshaft parts often lack the material quality, heat treatment, and manufacturing precision of high-quality components, leading to premature failure and higher total maintenance costs.

- Choose reputable suppliers: Opt for trusted driveshaft manufacturers, such as Shin Shin Long Precision Industrial (SSL-CV JOINT) in Taiwan. Their products undergo strict quality control and testing, ensuring longer lifespan and optimal performance, truly reducing long-term maintenance expenses.

Simple Maintenance, Long-Term Benefits

Driveshaft maintenance doesn’t have to be complicated. Regular visual inspections, paying attention to unusual driving noises, and selecting high-quality replacement parts when needed can significantly extend the lifespan of your driveshaft. This ensures driving safety and helps individuals and businesses manage repair budgets effectively.