Material Science Innovations Driving Driveline Breakthroughs

With the surge in demand for electric vehicles (EVs) and high-performance cars, driveshaft materials are undergoing unprecedented innovation. Modern custom driveshaft manufacturers must balance strength, weight, and cost, bringing carbon fiber, alloy steel, and composite materials into focus. Taiwan, as a major automotive parts hub in the Asia-Pacific region, is investing heavily in driveshaft material R&D.

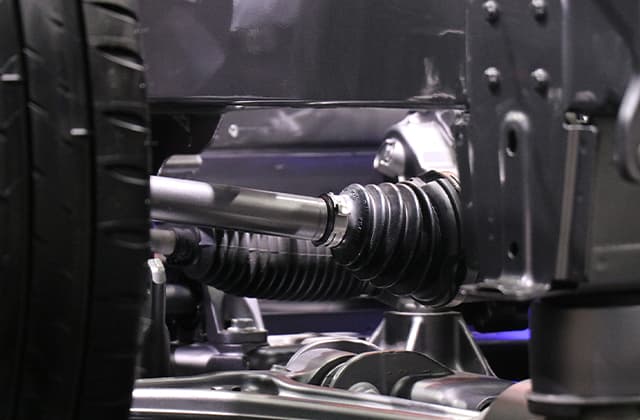

Alloy Steel: Evolution of a Classic Material

Stable Advantage of High-Strength Alloy Steel

Alloy steel remains the mainstream material for driveshafts, particularly high-strength chromium-molybdenum alloys capable of handling high torque. Modern alloy steel driveshafts, enhanced through precision heat treatment and surface strengthening, demonstrate excellent durability in electric trucks and heavy-duty vehicles. Cost-effectiveness and mature manufacturing processes make alloy steel a cornerstone for large-scale custom driveshaft projects.

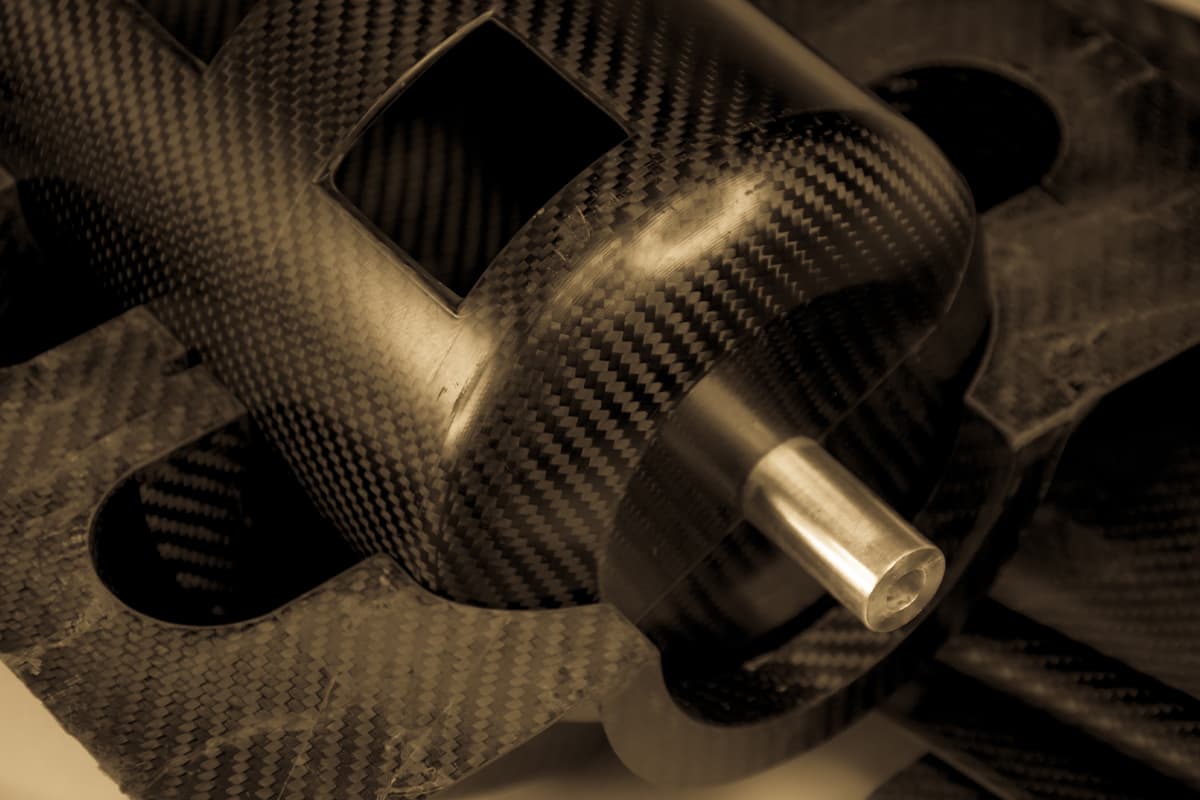

Carbon Fiber: The Lightweight Star

Breakthrough in Strength-to-Weight Ratio

Carbon fiber driveshafts, with extremely low density and high strength-to-weight ratio, are the preferred choice for racing and high-performance EVs. Compared to alloy steel, carbon fiber can reduce weight by up to 50%, improving acceleration and energy efficiency. Taiwanese manufacturers are actively developing advanced carbon fiber weaving techniques to provide specialized solutions for the EV racing and supercar markets.

Cost and Manufacturing Challenges Remain

Despite its exceptional performance, carbon fiber production costs are 3-5 times higher than alloy steel, limiting adoption in mass-market vehicles. Ensuring consistent quality and scalable manufacturing techniques remains a key challenge.

Composite Materials: The New Trend for Versatile Solutions

Unlimited Potential for Custom Applications

Composite materials combine the advantages of multiple substrates, offering flexible design options for custom driveshafts. Examples include aluminum alloy cores reinforced with carbon fiber or steel cores with composite outer layers, optimized for specific vehicle requirements. These composite driveshafts are particularly suited for electric commercial vehicles and specialty applications.

Material Science Leading the Future of Drivetrain Technology

Taiwan’s driveshaft industry is actively upgrading materials and manufacturing processes to meet the fast-growing EV and commercial vehicle markets. While alloy steel remains highly advantageous for its cost-performance balance, applications of carbon fiber and composites continue to expand. From robust alloy steel to ultra-light carbon fiber, and versatile composites, material selection reflects the automotive industry’s diverse development trends. There is no single “best” material—only the optimal solution for each application. As a leading Taiwanese driveshaft manufacturer, Shin Shin Long closely follows global advancements in material science, understanding the characteristics and applications of each material to provide clients with solutions ranging from standard specifications to highly customized driveshafts, meeting needs from commercial to racing, and from conventional to electric vehicles.