Fleet Pain Points: The Hidden Costs of Frequent Driveshaft Wear

In Taiwan, commercial vehicles such as trucks, vans (commonly known as “mini trucks”), and 5-ton carriers face the daily challenges of frequent start-stop operations and heavy loads, whether used for logistics, passenger transport, waste collection, or construction. Constant urban stop-and-go driving, steep mountain roads, and heavy cargo all put tremendous stress on the vehicle’s drivetrain. Among these components, the driveshaft, which transmits engine power to the wheels, plays a critical role. Its durability directly affects fleet efficiency and maintenance costs. Premature driveshaft failure not only increases repair frequency but also causes vehicle downtime—leading to significant and often unpredictable business losses.

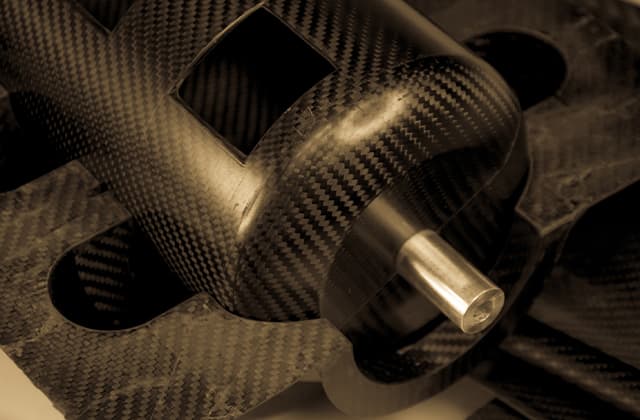

Materials and Design: Key Factors in Extending Driveshaft Lifespan

To effectively extend the lifespan of commercial vehicle driveshafts, choosing the right components is the first crucial step.

High-quality forged steel offers superior strength and toughness, capable of withstanding the extreme torque and impact generated by heavy-duty applications. Precision balancing reduces vibration during high-speed operation, minimizing wear on connected parts, while optimized CV joint designs ensure smoother and more efficient power transmission.

These invisible details are what truly determine whether a driveshaft can endure long-term operation in harsh conditions.

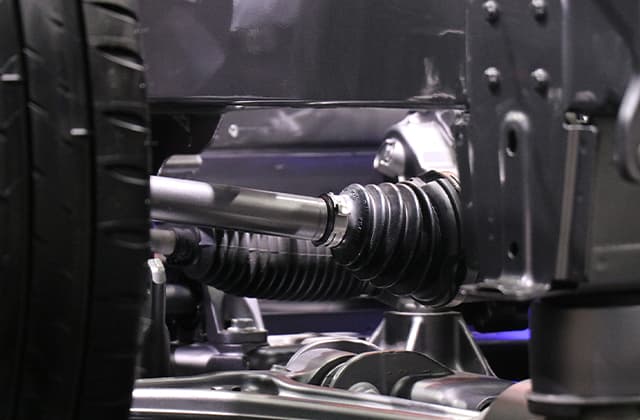

Adapting to Taiwan’s Environment: Special Considerations for CV Boots and Lubrication

Taiwan’s diverse climate and road conditions place extra demands on a key driveshaft component—the CV boot.

Humidity, rain, mud, and dust can cause standard rubber boots to crack and age prematurely, leading to lubricant leakage and contamination from dirt or moisture. Once the boot is damaged, the CV joint wears out much faster, eventually causing driveshaft failure.

To prevent this, it’s essential to use high-temperature, oil-resistant, UV-resistant materials (such as silicone or composite boots) and long-lasting lubricants formulated specifically for heavy-duty use. These measures are vital for maintaining driveshaft reliability in Taiwan’s demanding operating environment.

From Purchase Price to Total Cost of Ownership (TCO): Smarter Fleet Decisions

Savvy fleet managers look beyond the purchase price and focus on the total cost of ownership (TCO).

A cheaper driveshaft may seem cost-effective initially, but frequent replacements, labor costs, and vehicle downtime can result in much higher long-term expenses.

By investing in high-quality, durable driveshafts, fleets can significantly reduce failure rates, lower maintenance frequency, and improve uptime and profitability. Choosing ISO-certified suppliers with strong local technical support ensures consistent product quality and reliable after-sales service.

Choosing Local Expertise to Reduce Fleet Risks

In summary, for Taiwan’s commercial fleets facing the dual challenges of frequent start-stop operations and heavy loads, selecting driveshafts made with superior materials, precision design, and local environmental adaptability is key to improving efficiency and reducing costs.

Shin Shin Long Precision Industrial (SSL-CV JOINT), with decades of manufacturing experience, provides high-quality driveshafts that meet rigorous standards and offers customized solutions tailored to fleet needs.

In the long run, this represents a smart investment to ensure stable fleet operation and maintain a competitive edge in a demanding market.