Drivetrain Challenges Everywhere: From Racetracks to Farmlands

Whether on high-speed racetracks or expansive farmlands, driveshafts face very different challenges. Racing demands lightweight, high-precision components capable of handling sudden high torque, while agricultural machinery requires long-lasting durability and resistance to harsh environments. These differences highlight the need for customized driveshafts, a field in which Shin Shin Long Precision Industry has long specialized.

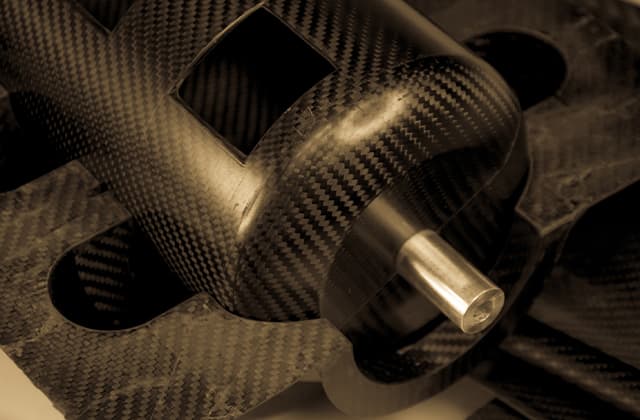

Racing Applications: Speed and Precision

Racing driveshafts must endure high torque and RPM, with lightweight designs reducing unsprung weight and improving handling. Using aerospace-grade materials, precision machining, and dynamic balancing, we ensure accurate and efficient power transfer, supporting outputs from hundreds to over a thousand horsepower.

Agricultural Machinery: Durability and Reliability

Agricultural driveshafts face mud, dust, chemicals, and long working hours, requiring high fatigue strength and corrosion resistance. We use specialized anti-rust coatings, reinforced protective sleeves, and sealed designs, combining durability with ease of maintenance for reliable operation throughout the harvest season.

Shin Shin Long’s Custom Craftsmanship

From concept design and material selection to prototyping and testing, we work closely with clients to create driveshaft solutions tailored to their applications. With decades of precision manufacturing experience, we transform diverse operational demands into high-performance, long-lasting driveshafts.

Future Trends and Value

Custom driveshafts integrate materials, manufacturing processes, and usage scenarios, supporting industrial upgrades in Taiwan and across Asia. With the rise of smart machinery and electrification, precise and durable custom drivetrain technology will continue to be a key driver of industrial growth.