Drivetrain Revolution in the EV Era: Opportunities and Challenges

The global electric vehicle (EV) industry is growing at an astonishing pace, signaling the most significant transformation in the automotive sector in over a century. This surge in the new energy market not only disrupts traditional internal combustion powertrains but also poses new challenges and opportunities for every link in the supply chain, including driveshaft (CV joint) manufacturers. For companies like Shin Shin Long, deeply rooted in conventional driveshafts, adapting to the unique technical demands of EVs will be key to capturing a leading position in the future market.

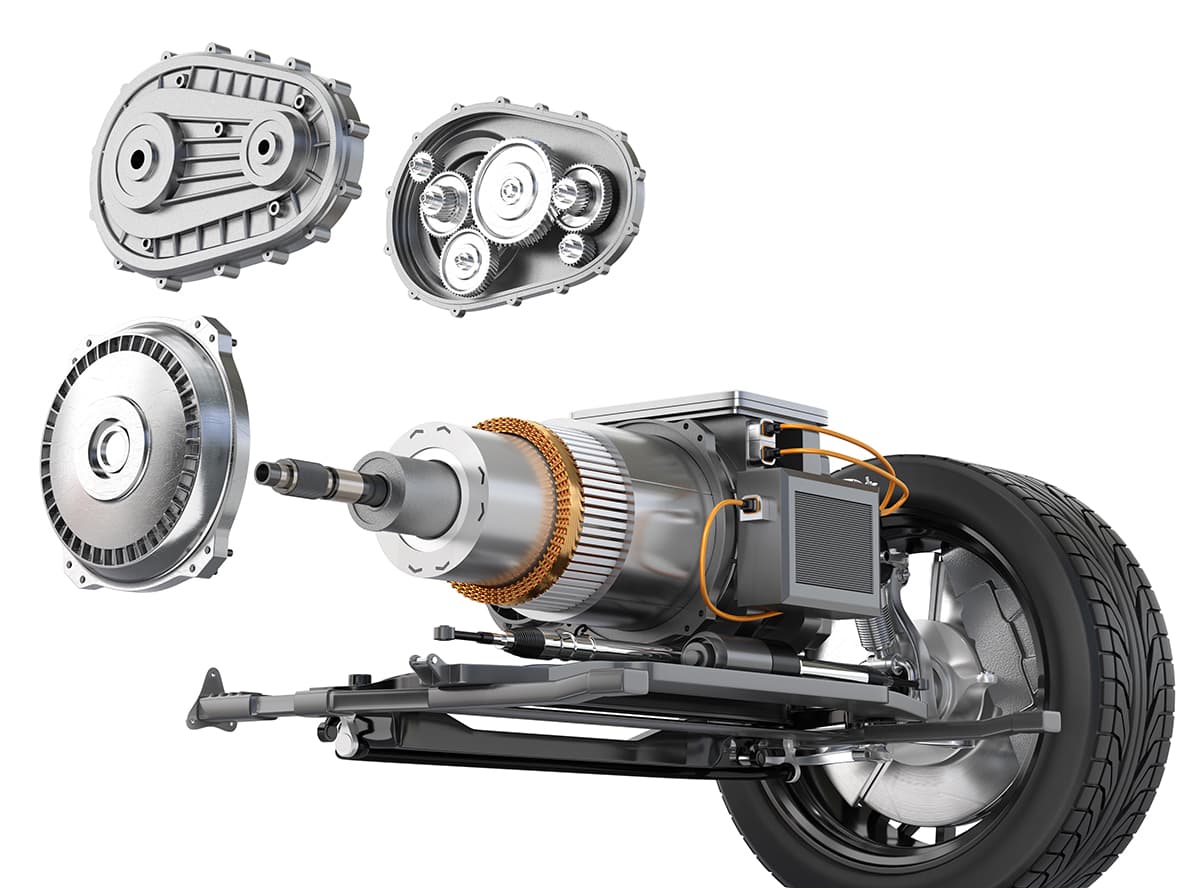

Unique Demands of EV Powertrains: Silent Operation and High Loads

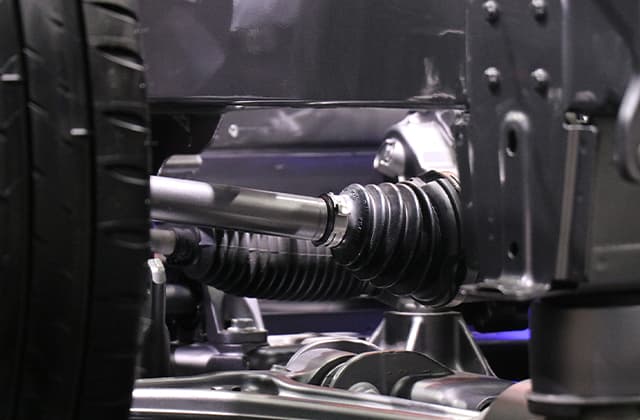

EV power delivery is fundamentally different from conventional vehicles. Electric motors provide instantaneous maximum torque over a wide RPM range, placing higher demands on driveshaft strength and durability. Equally important, EVs operate extremely quietly, meaning even minor noise or vibration (NVH) from the drivetrain is magnified, affecting the driving experience. Additionally, regenerative braking introduces reverse torque, creating new fatigue challenges. Traditional driveshaft manufacturers must thoroughly understand these characteristics to develop EV-compliant products.

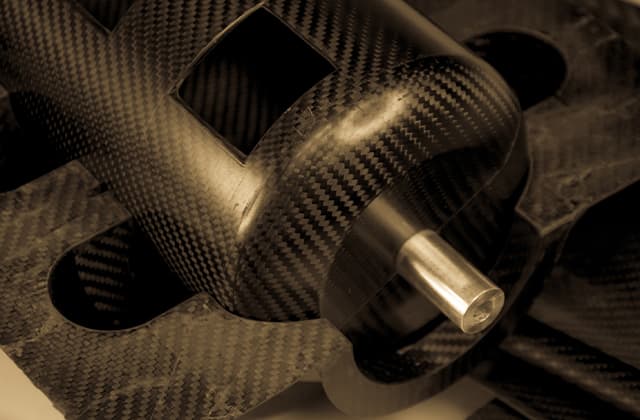

Technical Upgrades: Lightweight, Low-Noise, High-Strength Materials

To meet EV requirements, driveshaft technology must evolve comprehensively. Lightweight design is essential, achieved through high-strength alloys or composite materials to reduce unsprung mass while maintaining durability, improving range and handling. Advanced manufacturing and structural optimization minimize noise, vibration, and harshness (NVH). Key technologies include optimized spline designs, precise dynamic balancing, and advanced low-friction lubricants and seals—all critical for enhancing EV driveshaft performance.

Customization and Modularization: Integrating into the EV Ecosystem

The EV market is diverse, with different brands and models requiring highly customized driveshaft dimensions, torque capacity, and gear ratio matching. Traditional manufacturers need the ability to respond quickly and provide tailored solutions. Establishing close partnerships with OEMs, battery suppliers, and motor manufacturers—and participating early in vehicle development with modular drivetrain solutions—will be a strategic advantage in the new energy market.

Local Advantage: Taiwanese Manufacturing and Agile R&D

As a precision manufacturer with decades of experience in Taiwan, Shin Shin Long leverages high-quality local production and agile R&D teams to quickly meet EV customer customization needs. From material selection and structural optimization to process control, we are actively transforming to provide high-performance, reliable drivetrain components, helping drive the EV era forward.